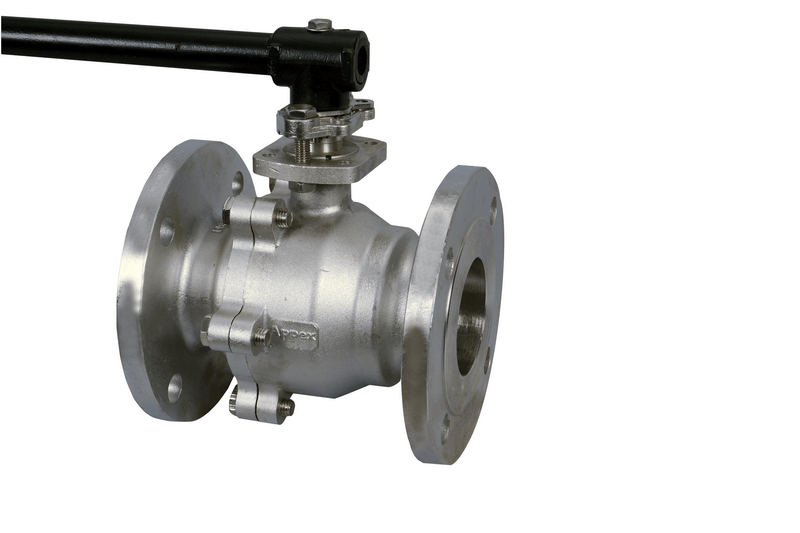

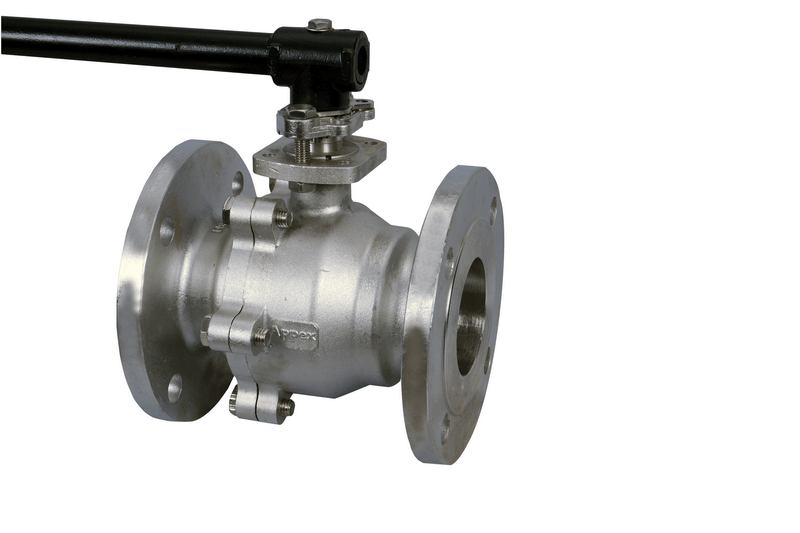

“Appex” gland type two piece / three piece / single piece design flange end ball valves are being constructed with all genuine working parts and giving guaranteed performance of 100 % tight shut off working. These super finished products ensure long life performance, low operating torque and striking performance. Design data of “Appex” gland type ball valves comply with latest relative international standards. All accurate and precise working through machining and assembly drawings are making really good and preferred quality products. Wide variety of materials of constructions can be offered for “Appex” gland type ball valves for particular range described in this catalog. These unique design valves have taken reputed place to many process industries due to some significant features like :

ISO 5211 MOUNTING PAD :

“Appex” ball valves bonnet is provided with an integral cast ISO 5211:2008 mounting pad for ease of automation. Pneumatic actuator or gear box unit can be fitted on actuator mounting flange with drilled and tapped hole without any modification in fitted valves.

Gland :

Investment casted gland is fitted with bolts on ISO 5211 mounting pad. 100 % fugitive emission free results can be obtained by tightening gland. Well tightened gland compressed gland packing uniformly at specific elasticity point and ensures desired long life air tight sealing . Gland also supports to reduce thrust loads as well as operating torque.

Locking arrangement :

Sheet metal cutting stopper plate is designed for dual purpose. One, it turns quarter from open to close position while operate valve. Second it can be locked with gland or ISO pad to prevent valve operating without permission or unauthorized operating.

Square stem and lever :

Close integrity between stem and lever is obtained by square design. Without thread heavy duty stainless steel stem gives easy operating with lower torque. Accurate made square insertion on lever provides desired integrity. Long life operating cycles can obtain with this unique design and removes chances of deformation in lever and stem.

Standards :

| Design and manufacturing standards : | BS EN ISO 17292 (BS 5351) / 12516 ASME B 16.34 API 608 / 6D / ISO 14313 DIN 3357 part – II |

| Inspection and testing std : | BS EN ISO 12266 (BS 6755 Part – I) / BS EN ISO 12569 ISO 5208:2008 API 598 |

| Face to face : | ASME B 16.10, CLASS 150 / 300 / 600 DIN 3202 F 17 (F1/F7) / F 18 (F4/F5) |

| Flange end connections facing standards : | ASME B 16.5 Rf serrated finish (AARH200), CLASS 150 / 300 / 600 BS 10 table D / E / F DIN 2501 PN 10 – PN 40 facing DIN 2526 |

| Pressure and temperature rating : | ASA 150 / 300 / 600 CLASS DIN 2401 (PN 10 -40) |

| Fire safe test : | API 607 / ISO 10497 |

| Fugitive emission : | EN ISO 15848 Part I & II |

| Wall thickness : | ASME B 16.34 |

| Screwed end : | ASME B 1.20.1 / 16.11 EN 12760 |

| Socket weld end : | ASME B 16.11 |

| Butt weld end : | ASME B 16.25 |